Our company has decided to add a new straight bar knitting machine to the machines already present in the company. This was done to offer a more precise and sophisticated custom service.

Knitwear department

The production

of MTM-branded knitwear

01

design/creation

/development

The development of a knitwear project is the first step towards achieving great results. MTM assists you in the designing phase of your product, providing you with custom services according to your needs.

02

design

After having understood the nature and the needs of the project, the next phase is the creation of a digital draw of the finished product. That is done to achieve a faster and more precise knitwear industrial production.

03

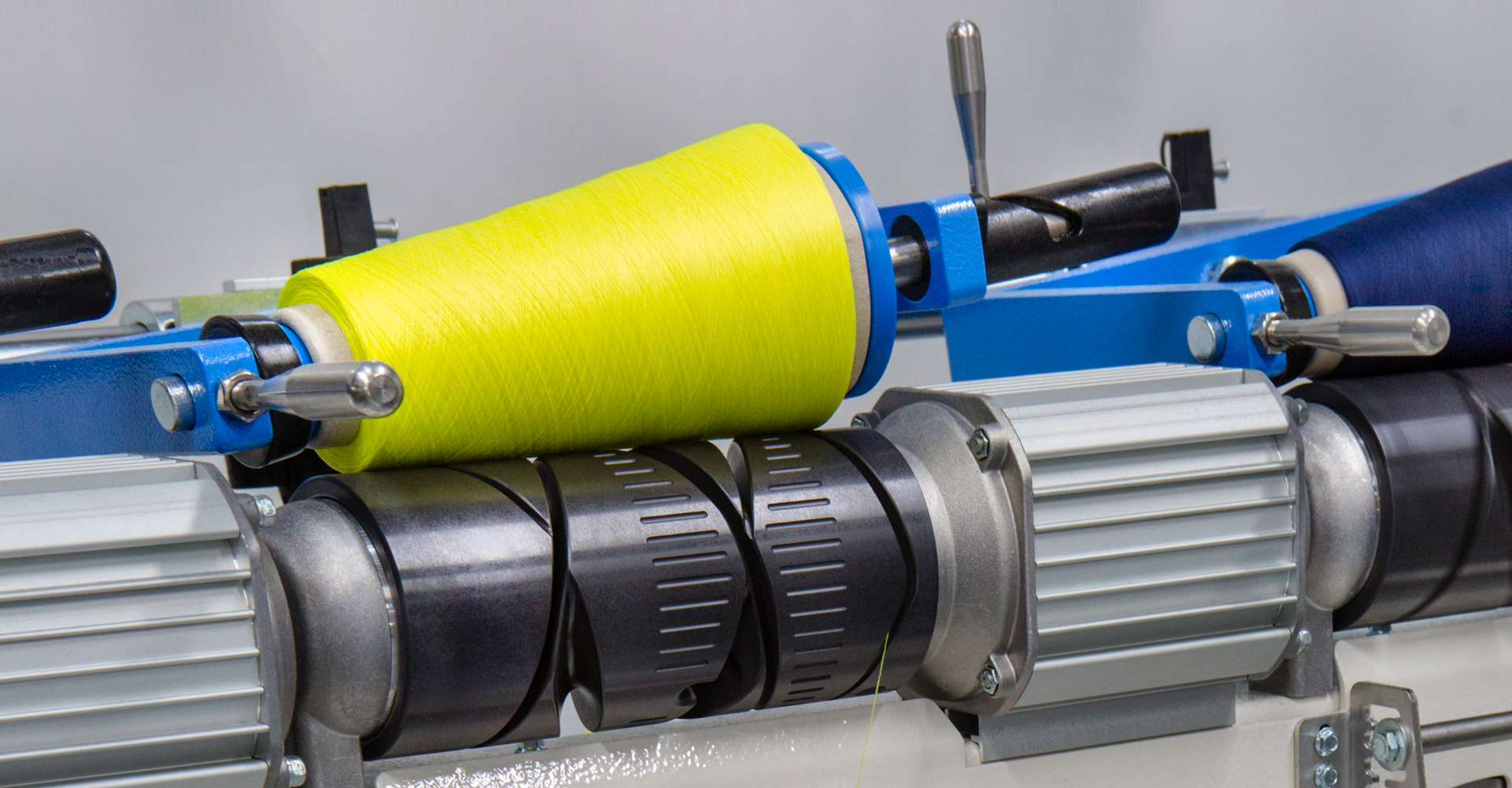

thread

/yarn selection

Choosing a premium thread/yarn is essential for a project. MTM assists and support you by showing you the best threads available to achieve an high quality knitwear production.

04

and washing

To keep having a reliable and secure industrial production, MTM gives the opportunity to all its clients to have a sample of the finished product realized and post produced with attention and care in evey detail.

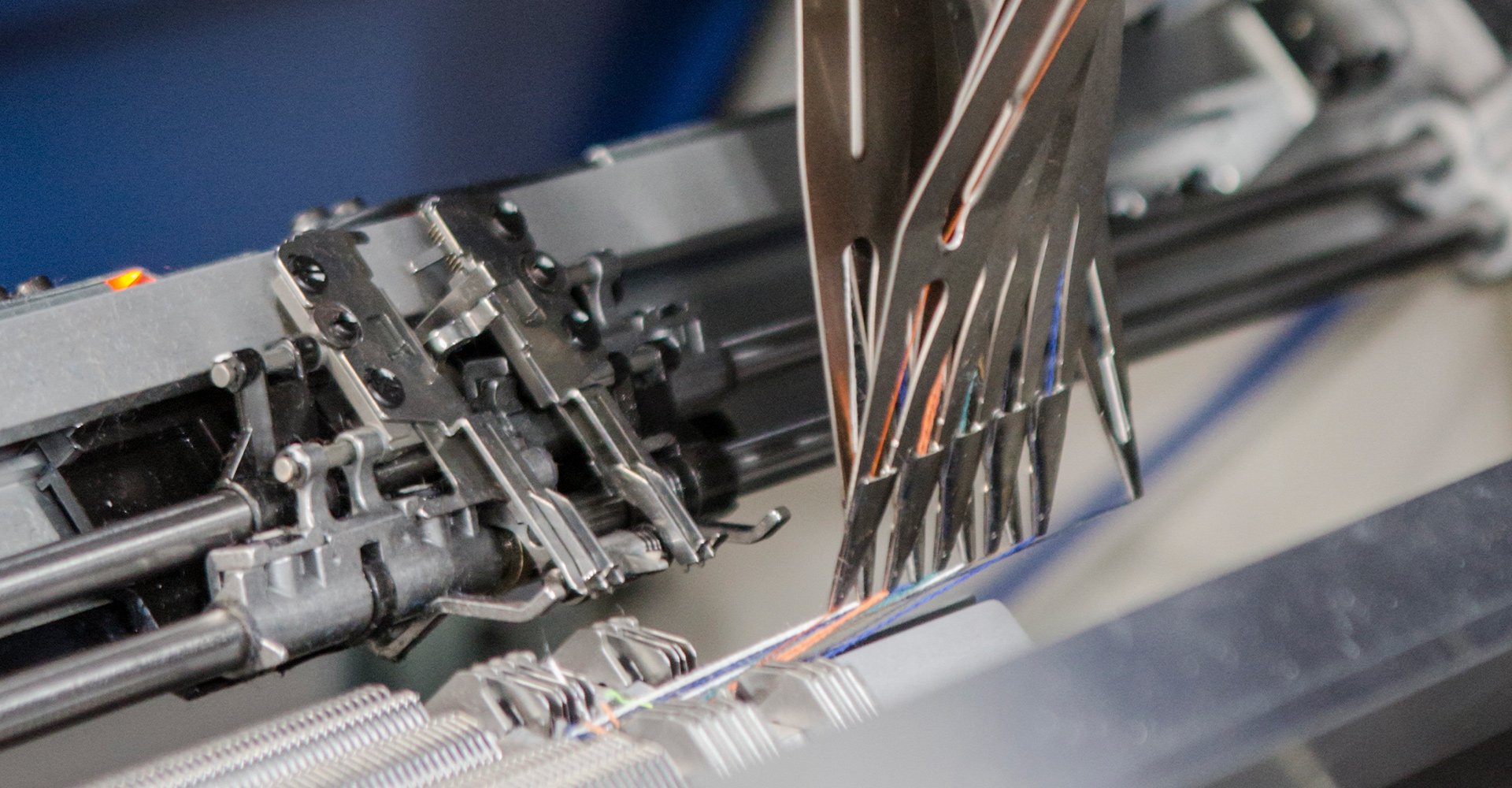

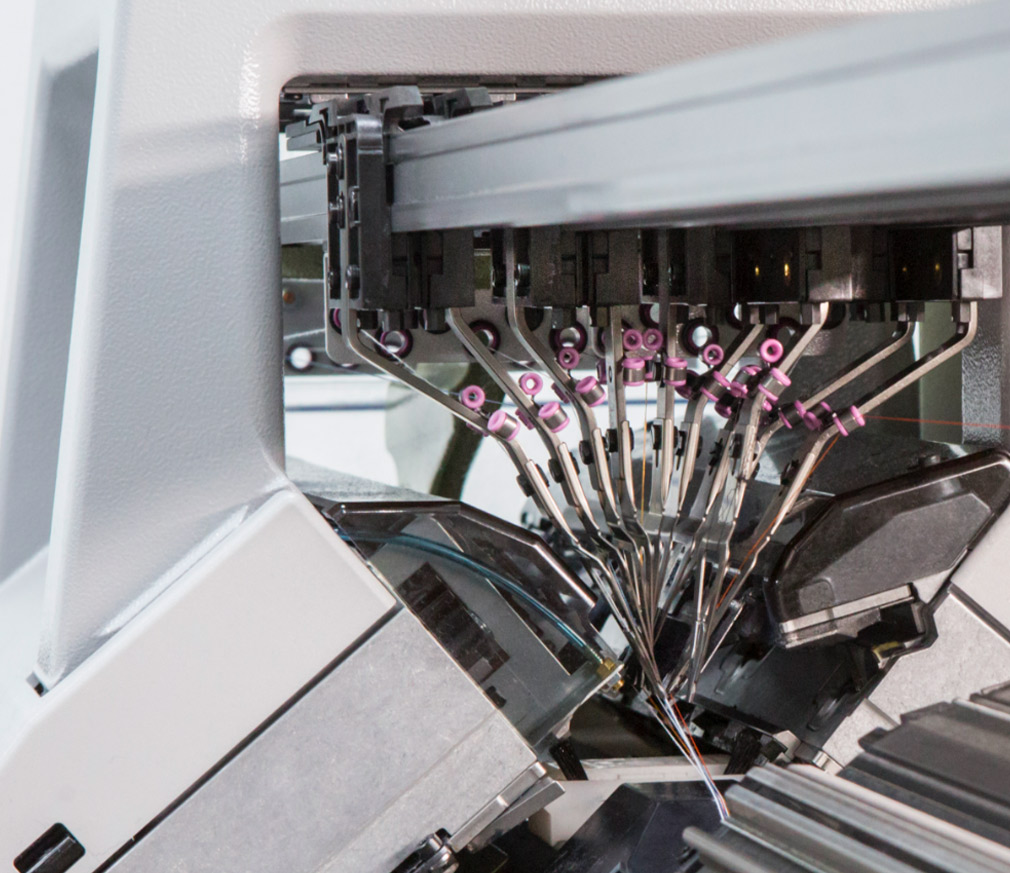

SVR123SP

Knitwear

machine

Technologically advanced and loop resser-equipped, the knitwear machine SVR123SP allows the realization of unique and particular knitch stiches, and it is designed for processing technical fabrics, uppers and padding.

Mini

SWG 091 N2

Electrolux's TD6 - 2MB

dryer and

WH6-16 washer dryer

Electrolux’s dryer and washer-dryer used in our knitwear production are equipped with a technology that allows energy savings. These machines allow our knitwear production to have high quality finished products, and they have drastically reduced costs and times.